Our Climate is changing around us faster than predicted. From more frequent and extreme storms to unprecedented heatwaves, we’re feeling the impacts of human-caused global warming. The world is already 1.1° C (1.9° F) hotter than it was between 1850 and 1900, the pre-industrial era. And while there’s no question that limiting warming to 1.5° C will be difficult, there’s also no question that we have the technology needed to do it—and that every tenth of a degree matters.

This has become a call to all and need for solutions and alternative solutions.

Bioethanol, a bioenergy that is renewable, low in pollution, and can be produced from materials that contain sugar and starch such as corn, potatoes, wheat, sugar cane, molasses, and others.

Bioenergy production from cultivated crops requires higher costs when compared to energy production from petroleum. Therefore, we need an alternative source of cheap and abundant raw materials.

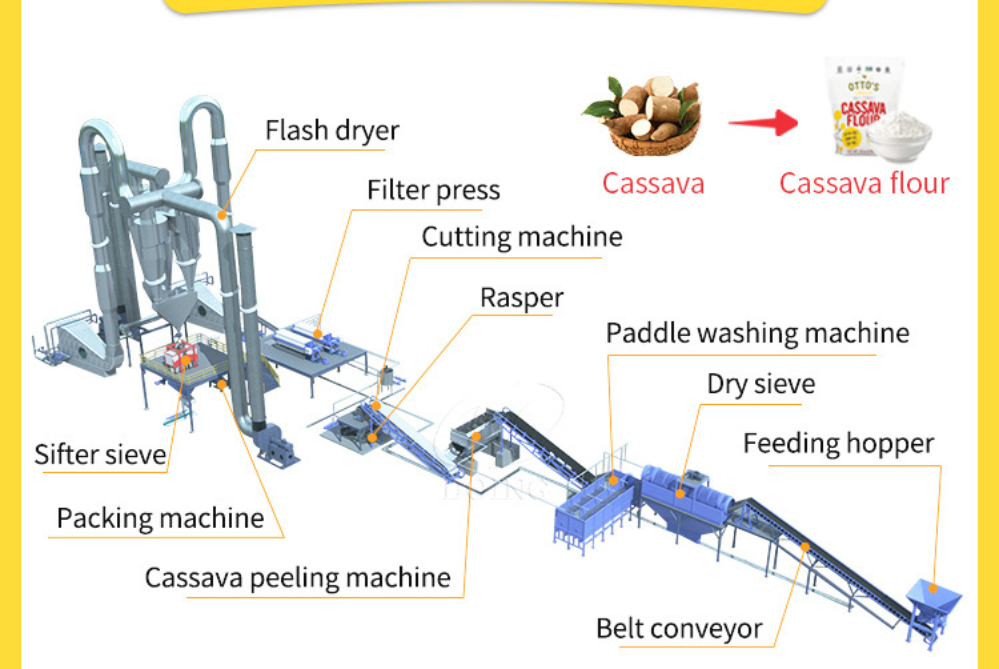

Cheap and abundant raw materials were wasted, one of which was found in the tapioca/ Cassava industry.

Process tapioca starch waste such as cassava peels and onggok (solid waste) can be used as an energy source in ethanol form.

The need for ethanol is increasing both as a solvent, disinfectant, raw material for chemical plants and as an alternative energy substitute for fuel. Biofire gel made from bioethanol from tapioca starch waste can support zero waste. Biofire gel is safer than liquid fuel (not easily spilled and evaporated).

We are championing this cause of Cassava/ tapioca processed ethanol to support the Globe, its people and to explore the full potentials within the value Chain

Classification | Industrial Grade | Pass | |

CAS NO | 57-55-6 | ||

Appearance | Colorless transparent Liquid | Colorless transparent Liquid | Pass |

Purity(%) | 99.5Min | 99.8 | Pass |

Moisture(%) | 0.08 Max | 0.08 | Pass |

Distillation Range | 183-190℃ | 184-187.4℃ | Pass |

Density(20/20℃) | 1.037-1.039 | 1.038 | Pass |

Color | 10 Max | 3 | Pass |

Refractive Index | 1.426-1.435 | 1.43 | Pass |